Harmonic Drive Transmission . The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Trusted industry leader for over 50 years. The harmonic drive® strain wave gear is made up of three basic components. Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals.

from conedrive.com

Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Trusted industry leader for over 50 years. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. The harmonic drive® strain wave gear is made up of three basic components. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%.

Harmonic Gear Solutions Harmonic Drive Gear Manufacturer Cone Drive

Harmonic Drive Transmission The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. The harmonic drive® strain wave gear is made up of three basic components. Trusted industry leader for over 50 years. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals.

From www.britannica.com

Harmonic Drive Description, Advantages, & Facts Britannica Harmonic Drive Transmission Trusted industry leader for over 50 years. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic drives can accommodate both forward and backward rotation with no need to. Harmonic Drive Transmission.

From www.alibaba.com

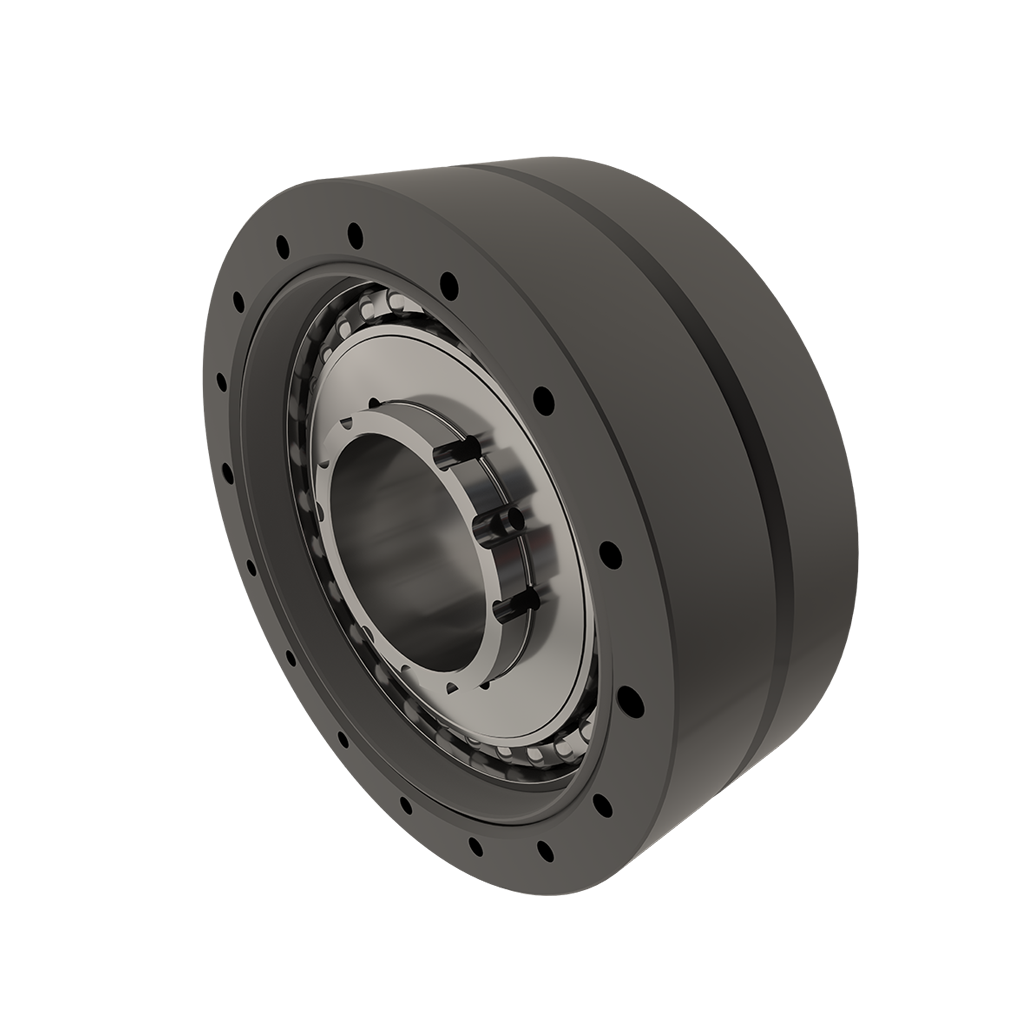

Harmonic Drive Gearbox Transmission Gear Speed Reducer With Compact Harmonic Drive Transmission The harmonic drive® strain wave gear is made up of three basic components. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Trusted industry leader for over 50 years. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the. Harmonic Drive Transmission.

From conedrive.com

Harmonic Drives Harmonic Drive Gear Solutions Cone Drive Harmonic Drive Transmission The harmonic drive® strain wave gear is made up of three basic components. Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drives can accommodate both forward and backward rotation with no. Harmonic Drive Transmission.

From servogearreducer.com

SHD Series Component Set of Harmonic Gearbox Servo Gearbox Manufacturer Harmonic Drive Transmission Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Trusted industry leader for over 50 years.. Harmonic Drive Transmission.

From www.smdgearbox.com

Wave Generator Harmonic Drive Transmission The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic. Harmonic Drive Transmission.

From www.sango-automation.com

China Harmonic Gear Drive Transmissions Manufacturers, Suppliers Harmonic Drive Transmission Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. The harmonic drive® strain wave gear is made up of three basic components. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. The dimensions. Harmonic Drive Transmission.

From www.sango-automation.com

China Harmonic Gear Drive Transmissions Manufacturers, Suppliers Harmonic Drive Transmission Trusted industry leader for over 50 years. Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar.. Harmonic Drive Transmission.

From www.precitorq.in

Precitorq Transmissions & Gear Boxes Harmonic Drive Transmission Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by. Harmonic Drive Transmission.

From atbautomation.eu

Harmonic Gear Wanshsin WSHG ATB Automation Harmonic Drive Transmission Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic drives can accommodate both forward and. Harmonic Drive Transmission.

From www.engineeringclicks.com

How does a Harmonic Drive work? Why are they used? EngineeringClicks Harmonic Drive Transmission Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Trusted. Harmonic Drive Transmission.

From www.ato.com

62 mm Strain Wave Harmonic Drive Gearbox, Ratio 30100 Harmonic Drive Transmission The harmonic drive® strain wave gear is made up of three basic components. Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drive® strain wave gearing utilizes a unique operating principle which. Harmonic Drive Transmission.

From www.controlsdrivesautomation.com

CDA One millionth gear Harmonic Drive Transmission Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. Trusted industry leader for over 50 years. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. The harmonic drive® strain wave gear is made up of three basic components. Harmonic drive® strain wave. Harmonic Drive Transmission.

From www.alibaba.com

Harmonic Drive Gearbox Csg321002uh Buy Harmonic Drive,Harmonic Harmonic Drive Transmission The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the. Harmonic Drive Transmission.

From www.youtube.com

Funktionsprinzip Das Harmonic Drive® Getriebe YouTube Harmonic Drive Transmission The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic. Harmonic Drive Transmission.

From www.sango-automation.com

China Harmonic Drive Gearboxes Manufacturers, Suppliers Factory Harmonic Drive Transmission The dimensions and weight of the harmonic drive parts are smaller than those of other transmission devices with similar. Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. Trusted industry leader for over 50 years. Harmonic drive® rotary actuators are the easiest solution. Harmonic Drive Transmission.

From conedrive.com

Harmonic Drive Gear Solutions Harmonic Drive Technology Cone Drive Harmonic Drive Transmission Harmonic drives can accommodate both forward and backward rotation with no need to change anything, and they retain the same positional accuracy on both spin directions. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Trusted industry leader for over 50 years. The efficiency of a typical harmonic drive measured. Harmonic Drive Transmission.

From conedrive.com

Harmonic Drives Harmonic Drive Gear Solutions Cone Drive Harmonic Drive Transmission The harmonic drive® strain wave gear is made up of three basic components. Trusted industry leader for over 50 years. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals.. Harmonic Drive Transmission.

From th.linear-rotary.com

China Harmonic Gear Drive Transmissions ผู้ผลิตผู้จำหน่าย โรงงานขาย Harmonic Drive Transmission Harmonic drive® rotary actuators are the easiest solution for your high precision motion control applications. The efficiency of a typical harmonic drive measured on real shaft to shaft tests by the manufacturer goes up to 90%. Harmonic drive® strain wave gearing utilizes a unique operating principle which is based upon the elastic mechanics of metals. Harmonic drives can accommodate both. Harmonic Drive Transmission.